Calf Beef Heifer Requirements Corn and Beet Root Beef Cattle Feed

The Cherry-red River Valley region of Minnesota and North Dakota, forth with the Yellowstone and Upper Missouri River Valley regions of Northward Dakota and Montana, are of import saccharide beet-producing regions. In fact, Minnesota, North Dakota and Montana ranked ane, three and 5, respectively, in sugar beet product in 2014. Together, these 3 states produced more than than 52 percent of the U.Due south. saccharide beet ingather in 2014. Processing plants in these regions refine the carbohydrate from the beets and produce large volumes of byproducts, which are useful feed ingredients for beef cattle producers.

Many producers are seeking alternative feeds to incorporate in their beef cattle diets, yet still come across the poly peptide and free energy requirements of the animals. Producers have a diversity of options to choose from in alternative feeds; however, the selection of those feeds depends on several factors, including availability and food limerick, as well equally storage and handling characteristics.

One possibility is to contain sugar beet byproducts into the diet. Beet byproducts are fed predominantly in northeastern Due south Dakota, western Minnesota and eastern North Dakota, as well as western Northward Dakota and eastern Montana. This is due to the availability and the perishable nature of the moisture byproducts.

The predominant byproducts fed in this region are wet beet lurid and beet tailings. These products are high in moisture (75 pct to lxxx per centum), which limits storage life and the altitude they can be transported economically.

Dried pulp and pelletized stale lurid also are available to producers; these dried products comprise about ten percentage moisture. In add-on, molasses and desugared molasses also are available as a outcome of sugar beet processing. The purpose of this publication is to depict the byproducts that are available and to requite feeding recommendations for each of the specific byproducts.

Saccharide Beet Processing

To better understand the nutrient characteristics of sugar beet byproducts, agreement the process that is used to extract carbohydrate from carbohydrate beets is of import. At the processing institute, foreign material, small beets and leaves are removed from the beets prior to processing. This fabric is known as "sugar beet tailings," which likewise is used as livestock feed.

The sugar beets are sliced into long strips called cossettes. The cossettes are cooked in hot h2o to remove the sugar. This process is called diffusion. At the terminate of the diffusion procedure, the hot h2o and sugar mixture is further processed into bulk or bagged sugar. The cossettes are conveyed to a pulp press, which squeezes some of the h2o from the pulp to facilitate transportation.

Pulp that volition exist marketed as dry shreds or pellets is conveyed to a pulp dryer. The pulp dryer dries the pulp to approximately 10 percent moisture. After drying, the pulp usually is pelleted to facilitate storage and transportation.

Molasses is produced during the refining process. The book of molasses produced varies, only is typically virtually 4 percent to five percent of the weight of the raw sugar beets. Molasses is separated from the juice (which contains the saccharide) through a series of centrifugation steps. Molasses contains 40 percent to 50 percent residuum sugar. Molasses commonly is refined farther through a procedure called molecular exclusion chromatography to produce condensed separator byproduct (CSB) or desugared molasses. This process removes a portion of the residue sugar and concentrates the remaining nutrients.

Nutrient Content, Byproduct Descriptions and Storage Recommendations

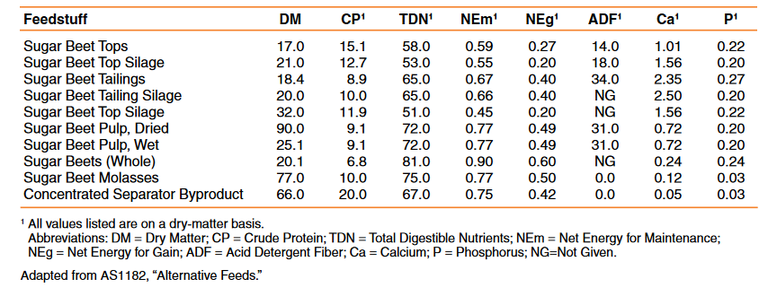

The nutrient content of a diversity of sugar beet byproducts is shown in Tabular array one. The nutrient characteristics and feeding recommendations for each byproduct are discussed below.

Table 1. Nutrient composition of diverse saccharide beet byproducts.

Adapted from AS1182, "Alternative Feeds."

Saccharide Beets

Occasionally, processors must dispose of whole sugar beets due to spoilage or excessively large crops. Whole beets can exist fed successfully to cattle. Whole beets are low in crude poly peptide (6.8 percent) merely high in energy (75 percent to 81 percent total digestible nutrients, or TDN). If possible, whole beets should exist broken upwards prior to feeding. Producers can utilize extended mixing times with a conventional mixer wagon to suspension up whole beets. In addition, some producers report success using manure spreaders to spread whole beets on stubble or stalk fields and assuasive cows access to the beets on the field. Choking may be a potential problem when feeding whole beets. Whole carbohydrate beets too can be fed past chopping in a tub grinder or fodder harvester to reduce the risk of choking. Some producers have noted success by using a forage harvester to chop the beets prior to feeding.

Whole saccharide beets can exist chopped and ensiled as a storage method. As with any ensiling procedure, good silage-making principles should be employed. These principles should include achieving the proper moisture level (typically sixty percent to 65 percent wet is required). Since raw beets comprise college levels of moisture than is optimum for ensiling, the addition of a dry ingredient is necessary to facilitate optimum ensiling.

Depending on what course of livestock the silage will be fed to, dry out ingredient choices could include chopped forage, grain screenings or other byproducts. The saccharide in the beets will provide the fermentable saccharide needed for successful fermentation. The pile should be packed and covered to exclude oxygen.

Beet Pulp

Beet pulp can be used finer every bit a supplement for gestating or lactating cows, equally an ingredient in backgrounding diets or equally a replacement for roughage in finishing diets. Beet pulp is relatively low in crude protein (8 pct), but relatively high in TDN (72 percent).

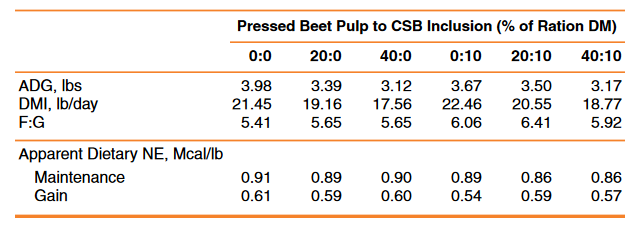

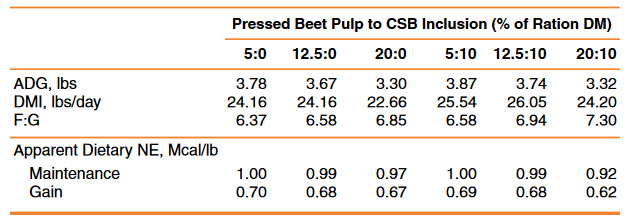

Research conducted at NDSU indicates that wet beet pulp can be included at up to 40 percent of the diet (dry-thing, or DM, ground) in backgrounding diets (Table 2). However, reductions in dry-matter intake will occur at inclusions greater than 20 percent of the diet. In finishing diets, wet beet pulp can be used as the roughage source, having an energy value greater than corn silage (Table 3).

Table 2. Effect of increasing level of pressed beet pulp and CSB in backgrounding rations on performance of steer calves (Bauer et al., 2007).

Table 3. Upshot of increasing level of pressed beet pulp and CSB in finishing rations on performance of steer calves (Bauer et al., 2007).

Equally a fractional or complete roughage replacement, it tin be included at v percent to fifteen percent of the nutrition in finishing rations (DM basis). Data collected at NDSU indicates pressed beet pulp has 94 percent the energy value of corn in backgrounding diets and 86 percent the value of corn in finishing diets (Tables 2 and iii). When wet beet lurid is fed at 20 percent of the diet DM, cattle volition swallow 30 to 35 pounds of wet pulp, which would be less than ane percent of their trunk weight on a DM ground.

Equally with any feedstuff, diets should be counterbalanced to meet the protein and free energy needs of the class of cattle that is being fed. There is no limitation on the corporeality of beet pulp that could be included in a beef moo-cow ration from a nutritional standpoint. However, in most practical applications, no more than fifty percent of the ration (DM basis) as beet pulp would be fed due to the reductions in intake that may occur at high levels, as well as moisture content and bulkiness of the diet.

Beet pulp is available equally either a wet (pressed shreds) or dry out byproduct (shreds or pellets). Because beet pulp contains large amounts of digestible fiber, it usually does not create a problem with acidosis for cattle consuming beet lurid. The economical distance that moisture beet pulp tin exist transported is limited by the moisture content.

Dry pelleted pulp should be stored in bins or article sheds to protect it from moisture and rodents. Wet pulp can be stored effectively in silage bags or in trench or bunker silos. Enquiry conducted at NDSU indicates wet beet pulp can be ensiled successfully with a diverseness of other feedstuffs as a ways to facilitate storage. Best results were obtained with the improver dry beet pulp or wheat middlings. Improver of carbohydrate beet tailings or dry feedstuffs such every bit wheat middlings or corn improved the quality of the silage through the addition of fermentable carbohydrate. Optimum moisture content for these silages is approximately 65 percent.

Beet Tops

Advancements in defoliator technology take limited the usefulness of beet tops since the beet tops essentially are mulched as they are removed. This causes difficulties in gathering the remaining remainder into a windrow or for cattle to graze the material.

Beet Tailings

Beet tailings consist of small beets, broken or damaged beets, soil and other strange material not suitable for sugar product. Tailings are high in wet (75 percentage to 85 percent) and can be quite variable in nutrient content.

With low levels of soil contamination and strange material, beet tailings have a feeding value like to or slightly greater than corn silage on a dry-matter footing. Nevertheless, high levels of soil or foreign fabric will reduce the energy content of tailings substantially. Choking may be a problem with beet tailings. Due to the high wet content, transportation is a major expense with beet tailings. Producers should evaluate transportation costs carefully before purchasing these byproducts.

Some producers have ensiled beet tailings successfully as a means of storage. Tailings should be composite with a dry feedstuff to reach a wet level that limits effluent losses from the silage pile. This can be accomplished through the addition of chopped forages, grain screenings or other byproduct feeds.

Molasses

Beet molasses is used primarily as a source of energy (75 per centum TDN) in animal feed, just it also is included in rations to meliorate palatability and to reduce dust. Information technology also is added to manufactured feeds as a folder for pellets and a carrier for urea or other nonprotein-nitrogen sources, vitamins and minerals. 15 per centum of the nutrition is the maximum recommended level. Beet molasses contains relatively loftier levels of potassium, sulfur, magnesium, sodium and chloride, compared with cereal grains.

Beet molasses must be stored in a well-insulated, heated tank. At temperatures above 110 degrees, information technology can be pumped easily with a 2.5- to 3-horsepower pump and 3-inch tubing.

Desugared Molasses (Concentrated Separator Byproduct, or CSB)

Desugared molasses, or CSB, is molasses that has gone through further refinement to remove remaining sugar. It is slightly lower in free energy (67 percent TDN), compared with molasses, just is higher in protein (20 percent rough poly peptide, or CP) and potassium. Enquiry conducted at NDSU indicates that information technology increases intake in a wide diversity of diets when fed at five percent to 15 percent of the diet.

Molasses and CSB are liquid byproducts. Tanks and associated pumping equipment are required to handle these byproducts. More than information on handling liquid byproducts is available at www.ag.ndsu.edu/pubs/ansci/beef/as1272w.htm. CSB can exist stored in an uninsulated tank with no additional heating required for pumping. Pump size should be ii-horsepower or larger, with a minimum tube size of 2 inches.

Obtaining Saccharide Beet Byproducts

Sugar beets typically are candy from early autumn (September) through late spring (May). Availability of sugar beet pulp and other byproducts declines through the summer months as companies sell inventory that accumulated during the processing season. In this region, Midwest Agri Commodities (www.mwagri.com) is the main supplier of sugar beet byproducts. Producers should work with commodity brokers to constitute contracts and ensure they have access to adequate amounts of byproducts for the winter feeding flavour.

Example Rations

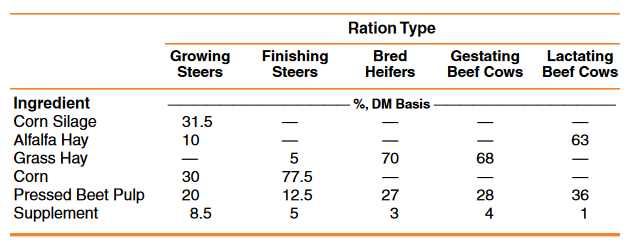

Table 4 gives example rations for diverse classes of beef cattle. These examples should serve merely as a full general guide. Ranchers and feedlot operators should piece of work with their nutritionist to determine appropriate levels for their livestock.

Table iv. Instance beef cattle rations using sugar beet byproducts.

The sugar beet industry produces a wide diversity of useful byproducts for livestock feeders.

The decision to incorporate saccharide beet byproducts into diets should be based on economics, local availability, and feasibility of storage, handling and feeding.

For the wet byproducts, careful attention should exist given to transportation costs and storage.

In addition, rations containing carbohydrate beet byproducts should be counterbalanced properly to achieve targeted livestock performance.

This publication was authored by Greg Lardy, NDSU Animal Sciences Section Head, and Rebecca Schafer, former South Dakota Land University Extension livestock educator.

buntonjuserebeaven.blogspot.com

Source: https://www.ag.ndsu.edu/publications/livestock/feeding-sugar-beet-byproducts-to-cattle